T-009

FANXI

8205100000

| Availability: | |

|---|---|

| Quantity: | |

Product Name Spiral Flute Taps

Material :High Speed Steel HSS 6542 Cobalt M35 M2

Holy Type: Blind Hole

Flute Type: Spiral Flute

Teeth :3/4 Flutes

Pitch: Coarse Pitch, Fine Pitch

Tolerance :H1, H2, H3, H4

Usage Mode :Machine Use

Surface Treatment :Titanium coating, Surface Nitriding Or Customized

Standards :DIN, JIS, BS, ANSI and ISO

Application : Internal Thread Cutting

Working Materials :Hardened Steel, Stainless Steel, Carbon Steel, Aluminum Alloy Stelel, Silicon Aluminum Alloy, Titanium Alloy

Working Machine : Lathe

Manufacturing process :Cut Thread, Ground And Fully Ground

Package :Plastic Box Or Customized

Feature:

1. High Speed Steel HSS Cobalt M35 Spiral Flute Machine Tap are made from 100% or pure raw HSS M2 with 5% Cobalt material, full grounded by CNC computer numerical control machine.

2. Spiral fluted Design helps evacuate chips up and out of the cut to reduce clogging, provide high performance in accuracy, chip removal, durability and efficiency.

3. Chips flow out against tapping direction(ejected from holes).

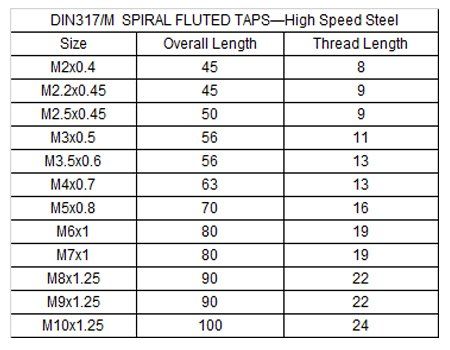

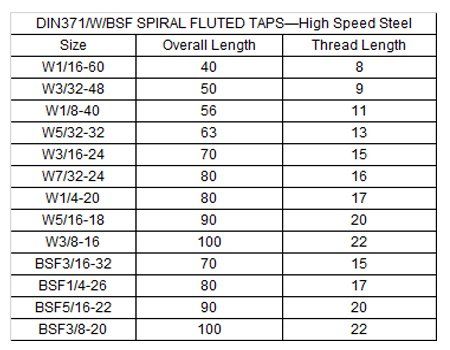

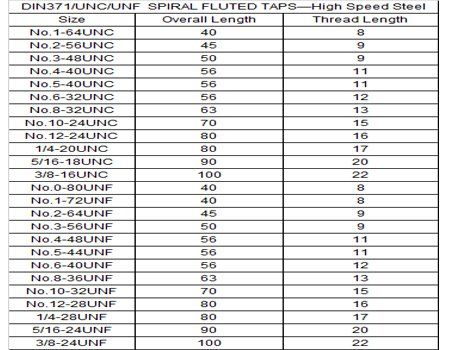

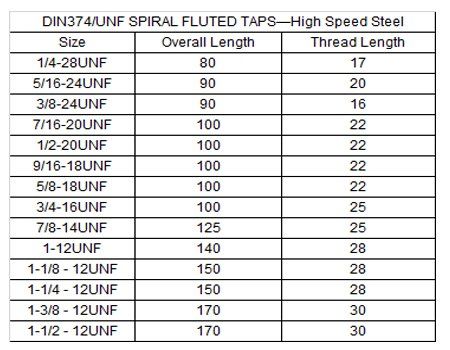

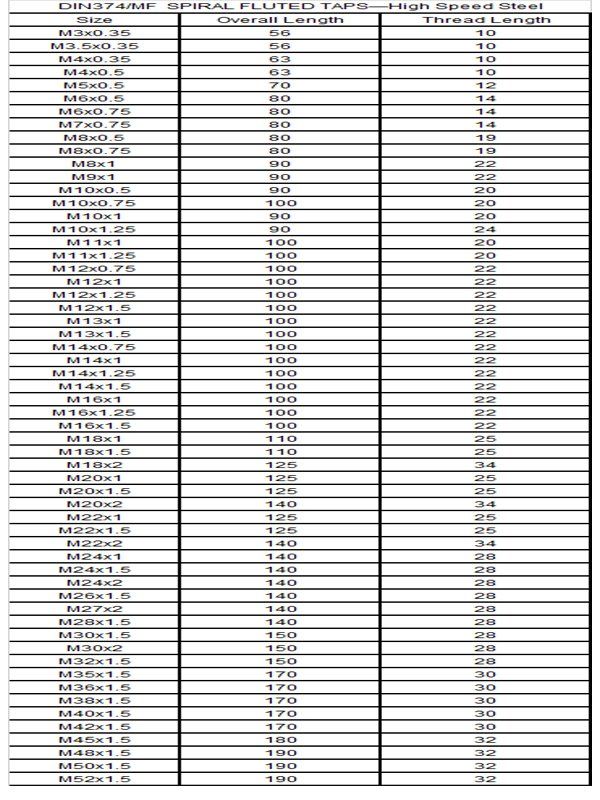

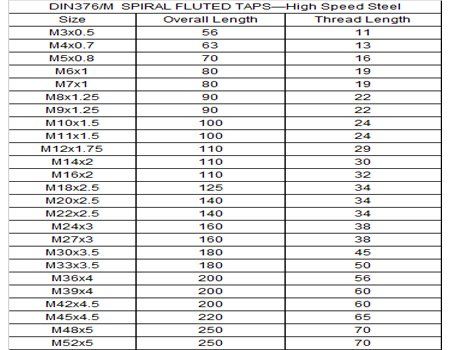

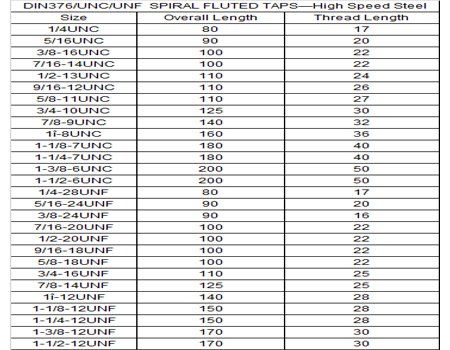

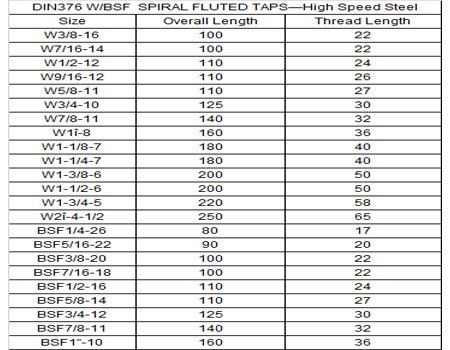

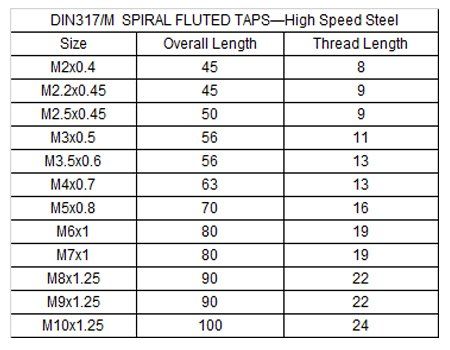

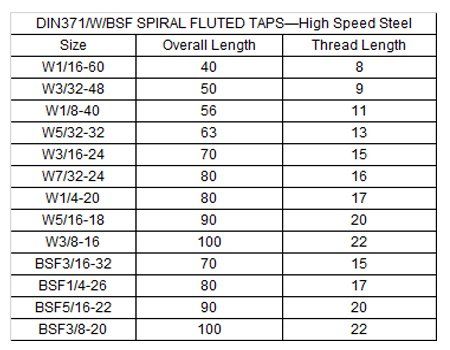

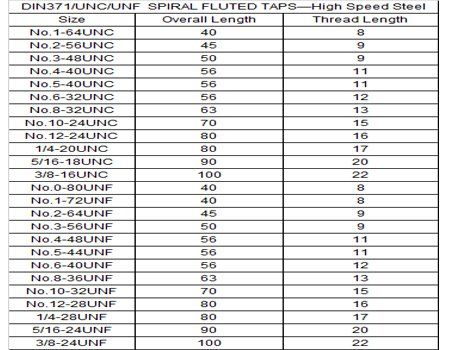

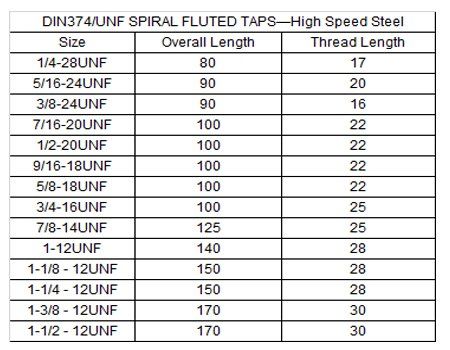

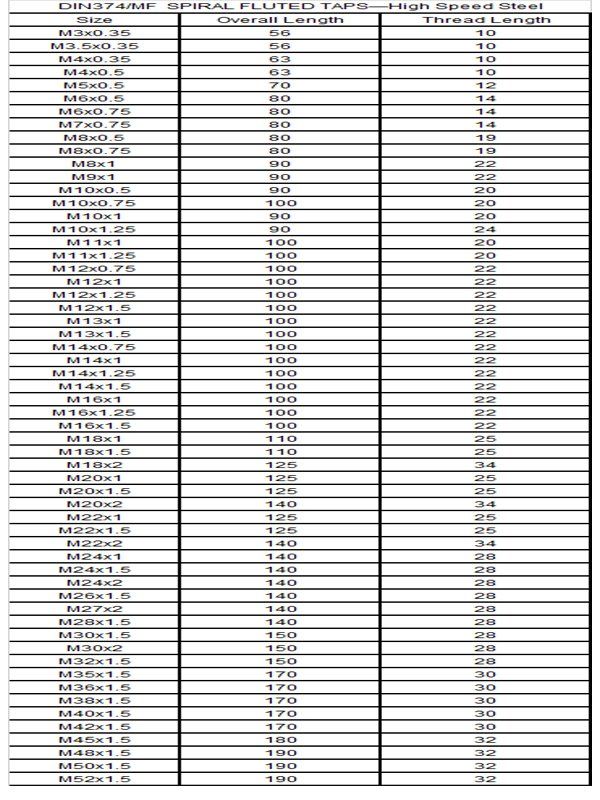

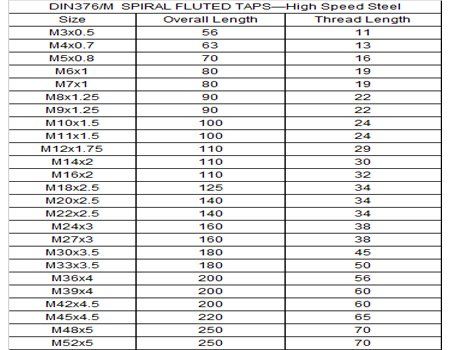

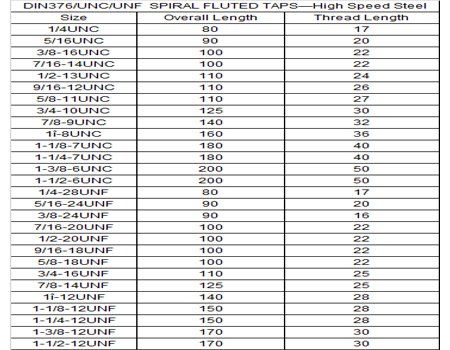

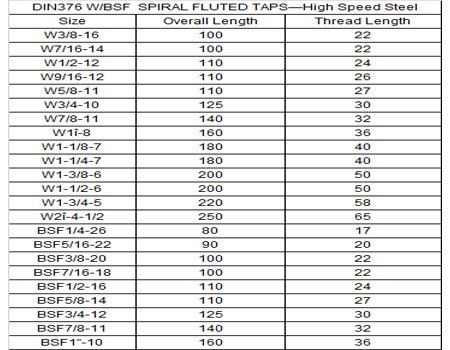

Metric / Fine Metric / BSW / UNC UNF, DIN & ISO are all available.

Product Name Spiral Flute Taps

Material :High Speed Steel HSS 6542 Cobalt M35 M2

Holy Type: Blind Hole

Flute Type: Spiral Flute

Teeth :3/4 Flutes

Pitch: Coarse Pitch, Fine Pitch

Tolerance :H1, H2, H3, H4

Usage Mode :Machine Use

Surface Treatment :Titanium coating, Surface Nitriding Or Customized

Standards :DIN, JIS, BS, ANSI and ISO

Application : Internal Thread Cutting

Working Materials :Hardened Steel, Stainless Steel, Carbon Steel, Aluminum Alloy Stelel, Silicon Aluminum Alloy, Titanium Alloy

Working Machine : Lathe

Manufacturing process :Cut Thread, Ground And Fully Ground

Package :Plastic Box Or Customized

Feature:

1. High Speed Steel HSS Cobalt M35 Spiral Flute Machine Tap are made from 100% or pure raw HSS M2 with 5% Cobalt material, full grounded by CNC computer numerical control machine.

2. Spiral fluted Design helps evacuate chips up and out of the cut to reduce clogging, provide high performance in accuracy, chip removal, durability and efficiency.

3. Chips flow out against tapping direction(ejected from holes).

Metric / Fine Metric / BSW / UNC UNF, DIN & ISO are all available.